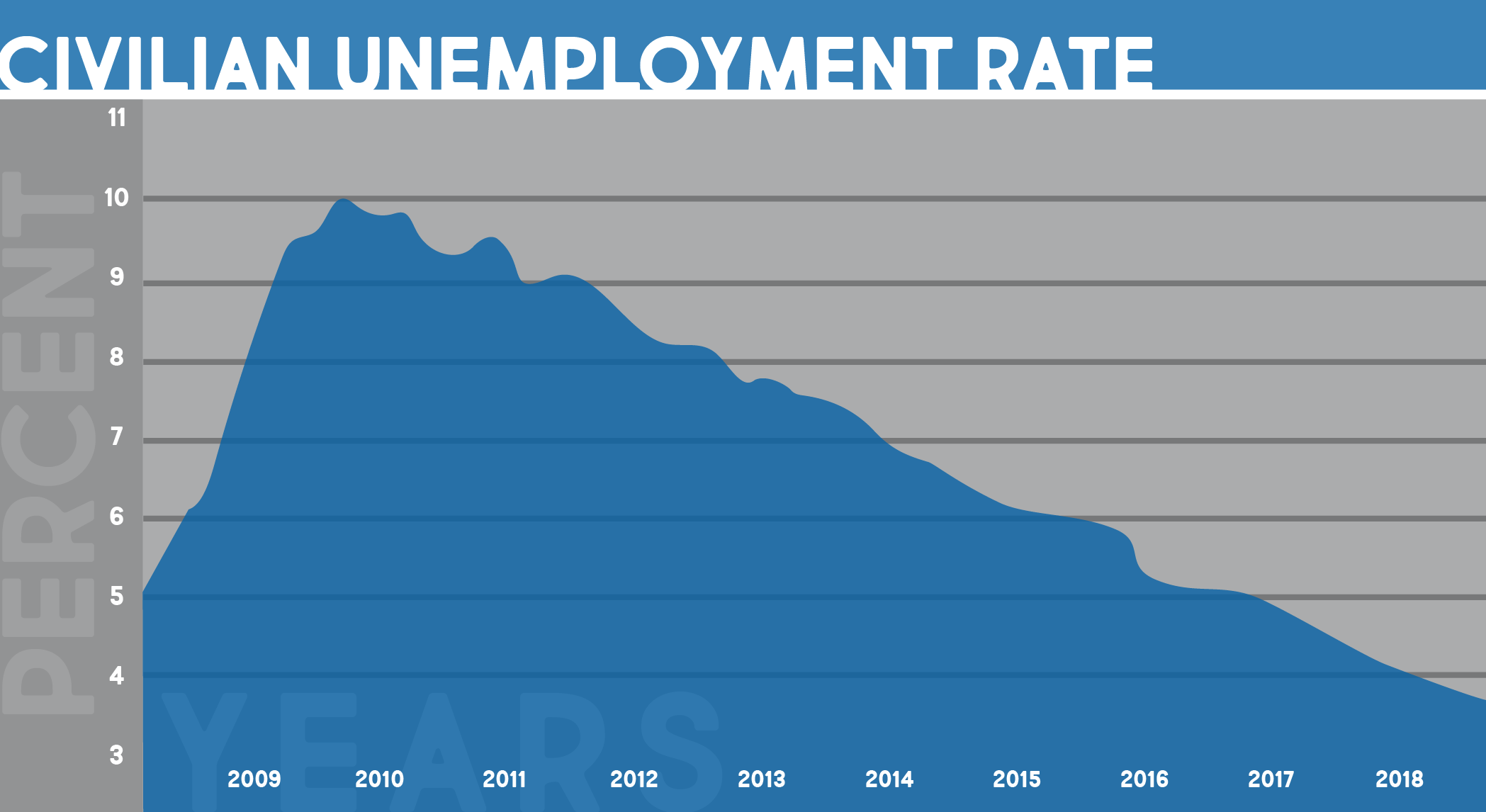

Talent shortages and employee turnover have long been common issues for businesses, but there are several current factors that are exacerbating the problem. The nation’s unemployment rate is at an uncommonly low level (it is under 4% – the lowest it has been in nearly 50 years) and some argue that the remaining 4% are largely unemployable. As many businesses are growing and looking to expand their workforce, the labor supply/demand ratio is at a serious imbalance, causing an environment where employers are aggressively pursuing employees of other companies, and some employees are switching employers for as little as a 25 cents per hour pay raise. It’s an all-out recruiting war and companies are scrambling to invent creative initiatives to recruit and retain talent.

Many businesses have not experienced significant turnover in the past – they have what they view as loyal and committed employees that have been with them for a long time. In these situations, companies tend to have a lot of “tribal knowledge” – key employees that have special knowledge that others in the company don’t, like what to do or who to call in critical situations, how to get a persnickety machine running again, what spare parts need to always be on hand, etc. These silos of knowledge within an organization, where one employee knows a process that has not been documented, can cause big financial losses for a business if one of those key employees becomes sick, incapacitated, or leaves the company. You can only imagine the chaos when multiple employees jump ship at the same time, taking that undocumented tribal knowledge with them! Ouch!

Some of the obvious ways to try to retain your employees is through better job conditions, increased compensation, better benefits, and more recognition. But sometimes that is not enough, and one way to mitigate the turnover risk is by documenting and institutionalizing standard processes across your organization. Don’t resist the turnover as much as making it less impactful.

Inoculate Your Company Against Employee Turnover

Documenting Processes

Defining current procedures is an important step to take toward minimizing the risks associated with employee turnover. When companies go through the process of defining and documenting all the steps a particular activity involves, they often find ways to refine and improve the process, eliminating unneeded steps. Having processes documented helps ensure that if an employee leaves, all of their knowledge doesn’t go out the door with them. It also helps onboard their replacement in a productive and efficient manner.

Standardized Processes

Many companies have a few common processes performed by a number of their personnel. For example, machine operators running the same/similar equipment or on different shifts, warehouse pickers/packers, purchasing expediters, etc. For these functions, there are many important benefits of standardizing the best proven practices. As you look to define the process, it is important to involve some of your better employees to make sure you understand what works and what doesn’t work – it is not always obvious unless you do the function repetitively. This engagement in the improvement process will likely drive buy-in and encourage an environment of collaboration. When the work is designed so that “anyone can do it” by having standard processes that include visual controls, such as color-coding and symbols, companies help ensure staff are aware of what is expected and how to succeed.

These types of documented procedures are critically important to companies that have seasonal labor or a large amount of “flex labor” – temporary employees that are brought in only when needed. Having standardized processes in place with supporting visual aides minimizes the onboarding time and improves efficiencies. Employees that feel like they understand what they are supposed to be doing are more engaged and also have lower turnover rates.

Cleaning Fish – A Streamlined Process

One of our clients processes seafood for distribution/sale to retail stores. We helped streamline a time-consuming process in their plant. They used to have one person clean an entire fish – a complicated process requiring expertise at several different techniques. We divided this work into smaller groups, where one person cleaned fins, one did bruises and one did blemishes, and created standard work processes for each. Each role individually was much easier than all 3 combined and could be done with little supervision. We used other techniques to train the supervisors to look for triggers that a process was not being followed. The client went from having 17 people on 1st shift cleaning fish for all 3 shifts, to 3 people on each shift cleaning fish for just that shift. Not only was this a reduction of almost 50% FTE, it also gave them much more flexibility in what the plant processed and when they processed it.

Communication

Of course, communication always is a key aspect for management to address. Sharing goals, objectives, and targets with employees and providing feedback about the progress toward achieving them, ensures they can be personally vested in the outcome. Their participation is crucial to navigate through many of the day-to-day challenges and to recognize what is or isn’t working so the company can adapt as needed. The old adage that “people don’t care what you know, until they know you care!” has never been more relevant than it is today when combating the dwindling numbers of available resources.

Indicators of Trouble Ahead

Regardless of how your company is being impacted by turnover today, it’s important to note that the labor crisis is not going away. All labor statistics indicate a growing obstacle. Therefore, it is good to be asking questions now about indications of trouble ahead and how to circumvent potential issues. A few questions to ask include:

- Do you have a long-term workforce of 10-15 years?

- Does productivity differ per shift/day/time or department/team?

- Is the productivity difference significant between the highest and lowest performers?

- Do you run simple products or not perform set-ups on third shift because of a talent gap?

- Are you already feeling pain from quality issues, output variation, or excessive downtime?

Knowing the answers to the questions above goes a long way to identifying if you have a problem and knowing how big it might be. However, partnering with experienced professionals can minimize those issues before turnover ever occurs. The ProAction Group is skilled at assessing processes, recommending operational changes, and implementing tools to evaluate progress. We welcome the opportunity to discuss your specific situation and can be contacted here.

If you enjoyed this article, please consider joining our email list so you never miss a post.